Abnormality Detection and Life Prediction

AI-powered prediction of equipment failures and lifespan

The ‘Anomaly Detection & Lifespan Prediction Solution’ analyzes sensor data to detect early signs of equipment failure and predict lifespan. By monitoring conditions in real time, AI enhances maintenance efficiency, reduces costs, and ensures stable production.

Use Cases

Discover how this solution can be applied in various scenarios.

Equipment Maintenance and Replacement Timing Determination

Swift Abnormality Detection Across Manufacturing Processes

Efficient Labor and Remote Supervision for Maintenance Staff

Solution Features

Learn about the key features that make this solution effective.

Select Appropriate Model, Including Non-ML, Based on Purpose

Effective Even With Limited Data

Leveraging Cutting-Edge Models for Optimal, Environment-Specific Deployment

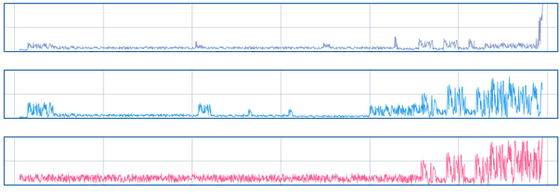

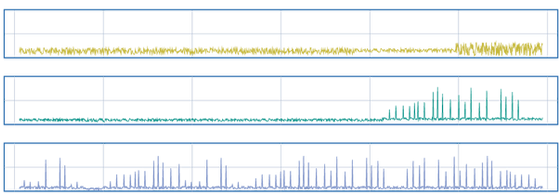

Traditionally, data has been monitored visually by skilled workers and anomalies have been detected based on empirical rules, but by training the latest machine learning models on data obtained from sensors, anomalies can be detected without relying on human labor. This reduces the burden of maintenance work, such as checking huge amounts of data and long hours of monitoring.

It is possible to pick out sensor data that indicates a high degree of abnormality from the vast amount of sensor data installed on the production line.

It is possible to detect abnormalities with high accuracy even during long-term monitoring.

Related Technologies

Solving industry challenges with AI technology.

Tech Insights

By NABLAS

Exploring the Potential and Risks of Generative Deep Learning.

While deepfake technology poses a significant threat, its underlying generative deep learning offers immense industrial value and transformative potential. At NABLAS, we highlight both the risks and opportunities of this technology, including deepfake detection, in our white paper.